Brisbane start up Vaulta has plans to shake up the lithium-ion battery market after spotting a neglected area in the otherwise state of the art field of electric vehicles.

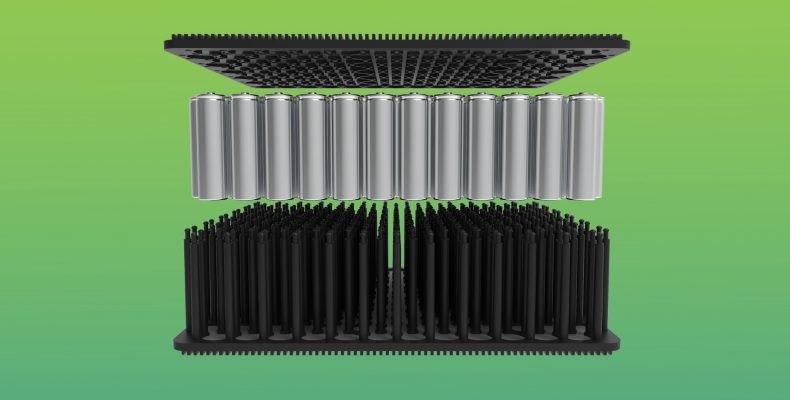

Vaulta has created a world-first battery casing technology to service the electric vehicle market, combining the functions of multiple battery casing parts into one, creating long-term efficiencies for EV manufacturers.

Founder Dominic Spooner says while all eyes were on the battery component of electric vehicles, he noticed the housings had not attracted the same level of attention. This piqued his interest as a designer of many years, and an urge to take on what seemed a troublesome, clunky or slow method.

“I just thought this is an area that need to be looked at, that everyone’s working on the gin and no one’s working on the tonic,”

– Mr Spooner, Founder of Vaulta

“We were seeing a huge amount of development in battery cell technology–a lot of cell chemistry and cell production developments–but the actual housings that went around these was really pretty much the same as when it first came in. Nothing’s really changed in those areas.”

Vaulta has reimagined casings with its proprietary polymer and is close to commercialising a simpler method for casing manufacture.

The housings are mostly injection moulded and made of advanced composite materials, a graphene and polymer blend with other ingredients in the composition as well as advanced processes that cannot be disclosed. The composites, used in conjunction with the mechanical design, provide customized characteristics in thermal and electrical conductivity, strength and weight.

Its fresh design dramatically reduces the number of parts, halves the cost to market for vehicle and battery manufacturers, reduces weight and size, offers enhanced passive cooling of the cell terminals and improved safety during both assembly and use.

Vaulta’s team of around seven, which includes ex-Tesla engineer Alan Zorkot, has raised $320,000 from ACAC Innovation, Artesian and other investors.

The company is looking for trial partners and expects to begin generating revenue by the end of this fiscal year, and to reach profitability by the end of 2021 into 2022.

The lithium-ion battery pack market is projected to reach US$74 billion in 2024, from today’s US$24 billion. Battery cell production will increase by 30 fold by 2030 as electric vehicles sales rapidly increasing worldwide, with the market estimated at US$420 billion by 2025.

The first of Vaulta’s advanced composite materials is less than 1mm thick, and is electrically and thermally conductive for transporting electrical current through the battery pack. It’s a lighter alternative than copper, aluminium or nickel which Mr Spooner notes “cost money and take up weight and size.”

The second advanced composite material is thermally conductive only, but is also stronger and lighter than current market offerings.

“That design allows us to help the battery cells right at the source of the heat, which is the terminals, the positive and the minus, and that’s going to help the life of the battery and should help the performance of the battery as well, and make it cheaper.

Vaulta is ready to trial its methodology and Mr Spooner says there is already a product that can be “commercialised right now with the materials that we’ve developed”. The plan is to target battery manufacturers first, with the possibility of going directly to car manufacturers later on.

“We’re not thinking it is going to be that easy, that’s for sure,” Mr Spooner says. “They’re certainly going to take some convincing to start with., I don’t think you can just knock on the door of Ford and Volkswagen and say ‘Here you go, here’s some technology’. There’s a little bit more of a process than that.”

Vaulta also predicts better re-use, saying these batteries could have second applications in smaller electric vehicles like scooters and skateboards.

“It’s a really overlooked area,” Mr Spooner says.

Oct 2020